+1 919-542-4417

Blog Full

- Home

- Blog Full

-

19

Aug

2021

Anyone who has ever commissioned a drive in Siemens TIA Portal knows that it can be a hassle. On top of that it can become very time consuming if multiple drives need to be commissioned. The tools built into TIA portal offer great flexibility, however

-

18

Nov

2020

By Autonetics In News

Autonetics is excited to announce that our business has moved to a new headquarters in Moncure, North Carolina. We are thrilled about this move! Oftentimes it was evident to our team that our company had outgrown our old facility in Cary. This new space will

-

08

Apr

2020

By Autonetics In Factory Automation

Incorporating a custom automated inspection system can provide many benefits to your industrial automation and quality control process. You can increase the rate of production, the quality of your items, and the efficiency of your entire operation. However, if you need to modify the system

-

03

Apr

2020

By Autonetics In Factory Automation

Within the field of industrial automation there is an increasing need to protect our skilled workforce from potentially catastrophic interactions with powerful automated machinery. With this as a primary concern, designers must also account for machine longevity, maintainability and cost of ownership. The standard approach

-

21

Mar

2020

By Autonetics In Factory Automation

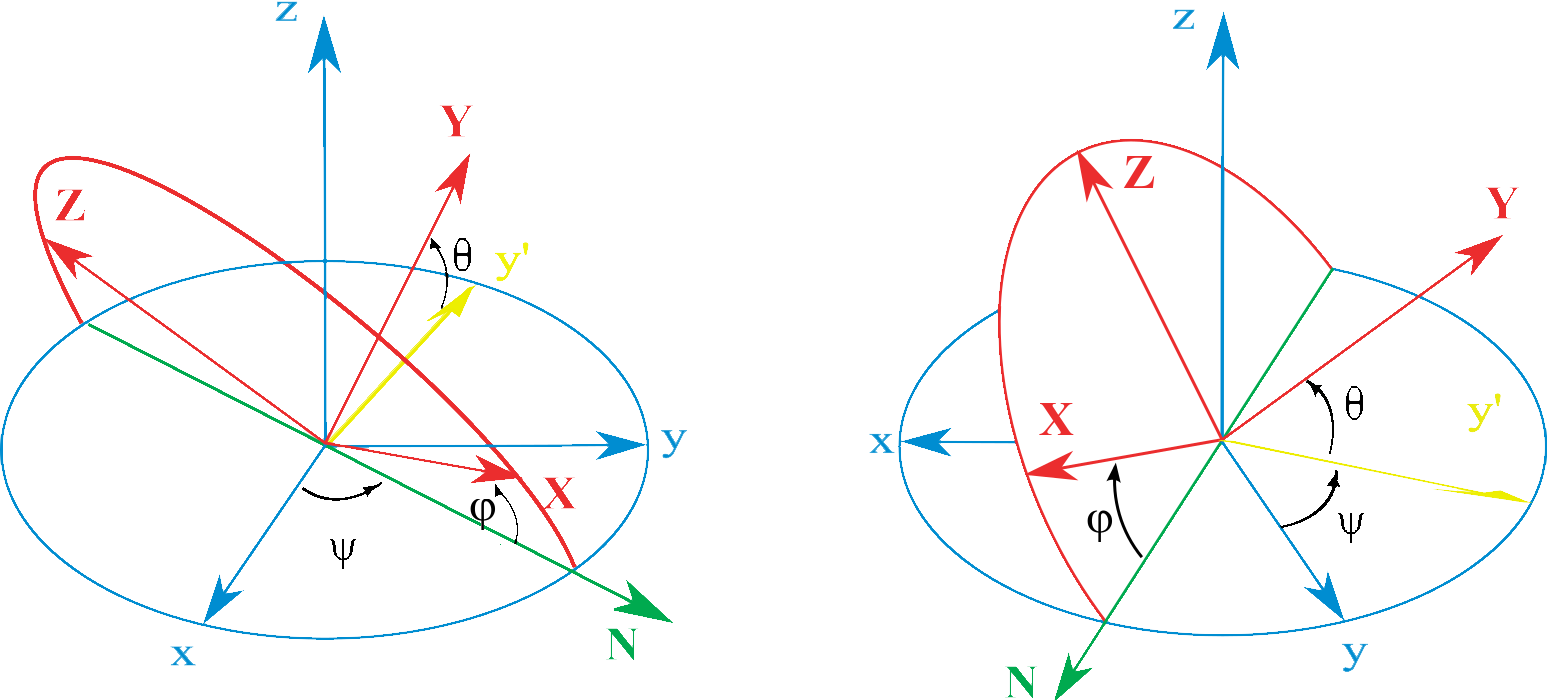

Challenges in part scanning The physical alignment between a part to be scanned and the scanning hardware on a robot end effector is never perfect. This fact can lead to calculation errors if left unchecked. A simple three-dimensional movement from point A to Point B

-

17

Jul

2019

By Autonetics In Factory Automation

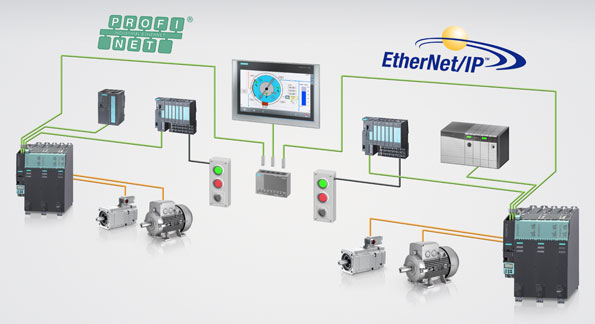

Traditionally, automation equipment is controlled by a PLC – the logic brain of a system that handles the flow of operation, processes I/O, and communicates with other networked equipment.The majority of Autonetics’ products are controlled by an industrial PC (IPC). We eschew the traditional route

-

18

May

2019

By Autonetics In Metrology

The AGU is Autonetics’ flagship product – the world’s first and only production ready, in-process, high-speed, non-contact thread inspection system.Pipe mills across the world use Autonetics technology every day. United States Steel is one such company. At their Lone Star Tubular Operations facility, two AGU’s

-

05

Mar

2019

By Autonetics In Metrology

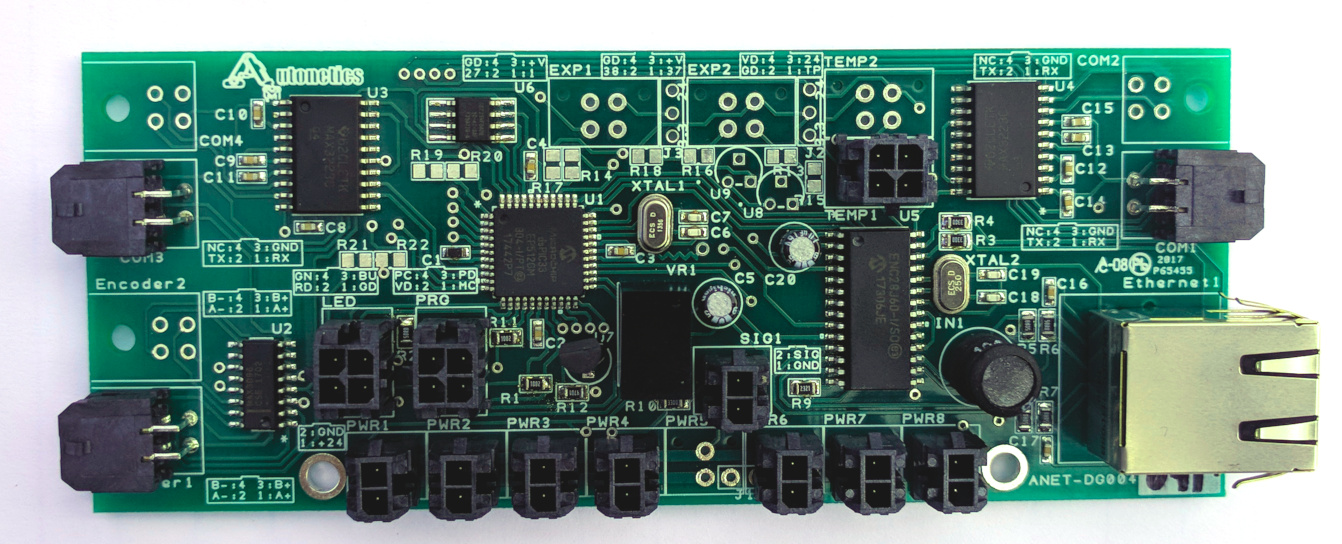

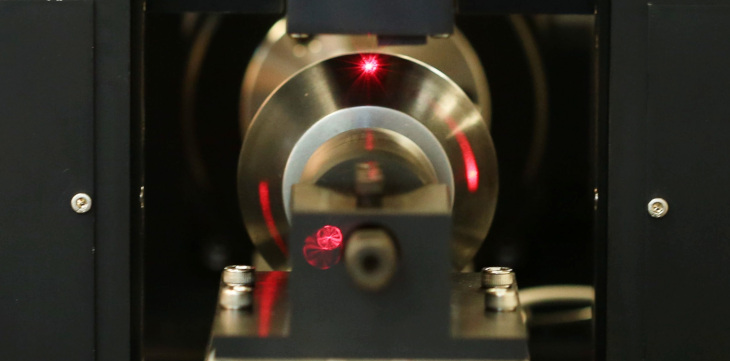

At Autonetics, we design and build each gauge to the needs of our client. Many of our gauges use commercial off-the-shelf hardware, along with hardware produced in-house. With the variety of sensor systems available on the market, when and why would we decide to use

-

25

Feb

2019

By Autonetics In Metrology

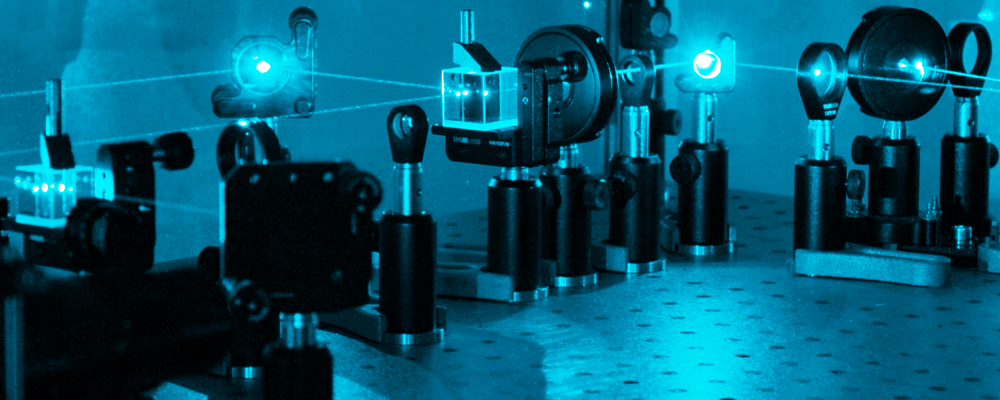

In the field of laser metrology two of the major concerns are accuracy and repeatability. These are crucial metrics for ensuring a system is performing as expected in its role to improve quality control. At Autonetics we have a rigorous development process that ensures our

-

31

Jul

2017

Autonetics offers research and development (R&D) services for automating part inspections with the latest non-contact laser sensors. In a typical R&D project, Autonetics evaluates the interdependencies between cycle times, dimensional data callouts, tolerances, surface areas, individual part sizes, part-family size ranges, part handling, personnel involvement