Anyone who has ever commissioned a drive in Siemens TIA Portal knows that it can be a hassle. On top of that it can become very time consuming if multiple drives need to be commissioned. The tools built into TIA portal offer great flexibility, however this can make them tedious or confusing. This is tolerable if the flexibility is needed, but most of the time a simple setup using an induction motor with Volts/Hertz control is all that is required.

At Autonetics we are always trying to understand and improve our work at a fundamental level. This led us to the task of creating our automatic drive commissioning tool to be used with Siemens drives. Using this tool we are able to fully commission a drive, bypassing 100% of the TIA Portal commissioning tools.

Framework

The following characteristics were decided upon as requirements.

- The ability to commission multiple drives quickly.

- The ability to be used by someone with minimal knowledge of drives and motors.

- Streamlined process requiring only the most accessible information.

- The ability to use the same tool to create complex drive configurations if desired.

- A complete solution that yields a ready to use drive.

- It must not require any custom telegrams to be used.

- The ability to safety commission the drive after the main commissioning has been completed.

- The ability to save the drive parameters as well as hardware reset the drive

programmatically.

We are proud to say we have successfully created a tool that does all the above.

How does it work?

The ability to commission multiple drives quickly.

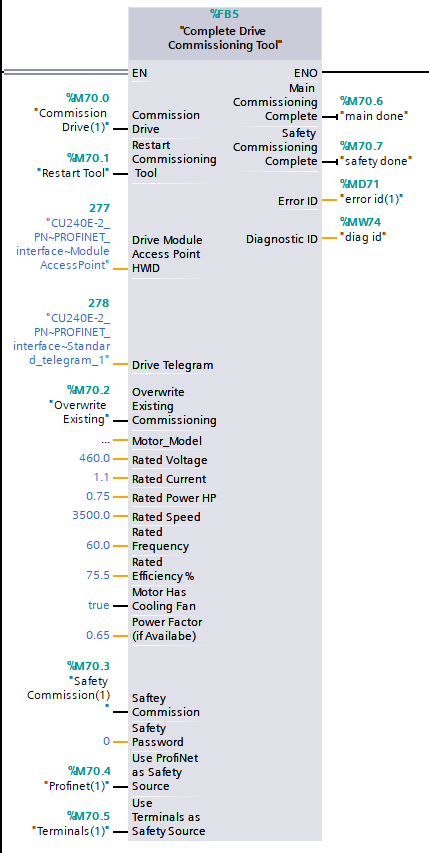

To achieve this requirement, we decided on creating a function block that gets added to the PLC program. In this way a block can be added for each drive so that on the first scan cycle of the PLC program, all drives added to the project are automatically commissioned with no human effort required.

The ability to be used by someone with minimal knowledge of drives and motors, and a streamlined process requiring only the most accessible information.

We wanted anyone who knows how to add a block to a PLC program to be able to use this tool. To achieve this, we chose to have the tool set up drives using the following defaults.

• Induction motor

• Volts/Hertz control

The only input required is the motor nameplate information. Each of which is clearly designated on the block with explicit naming such as “Rated Voltage” or “Rated Efficiency”. We also settled on a single clearly marked unit system using US customary units. Motors with other unit systems may still be used simply by converting the power in Watts to the required power in Horsepower, using any number of online conversion tools.

Using industry standard assumptions, the rest of the drive settings are automatically calculated. For example, the max speed of the motor is assumed to be 150% of the rated speed, plus 50 RPM. This allows use of the motor in both the rated torque and rated power regions. The 50 RPM buffer ensures that the full 150% speed can be used without worry of nuisance trips of the overspeed fault from overshoot or minor inaccuracies in the drive.

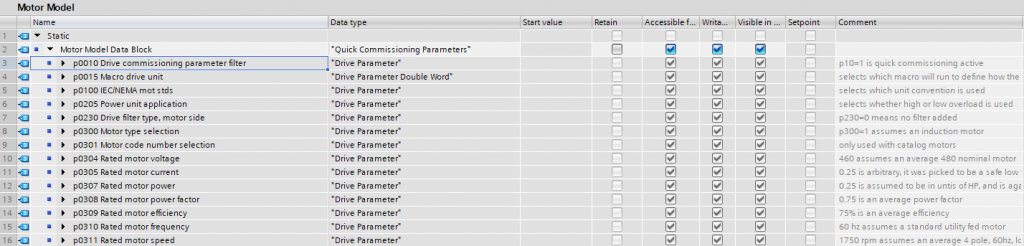

The ability to use the same tool to create complex drive configurations if desired.

We wanted to maintain the full drive functionality should a more advanced user desire to create a non-default motor setup. To achieve this, we have an included motor model data block input. This data block gives full access to set any parameter, such as max speed. If this input is used, it supersedes the default program. An advanced user will have full control of all motor options by simple changing any desired parameters in the data block. Additionally, each block created for a specific motor model can be saved in a library. This not only allows advanced users to quickly commission commonly used motors, it also allows users with minimal drive knowledge to commission drives with complex settings.

A complete solution that yields a ready to use drive and does not require any custom telegrams to be used.

Upon completion of the standard TIA Portal commissioning wizard the drive is still not ready. It requires additional human interaction to switch the drive on for the first time to trigger measurements of the physical motor characteristics. We have automated this process by programmatically switching the drive on the first time to trigger the measurement. We do this by controlling the drive using the standard control word one which is automatically created by the drive when added to the program. No custom options are needed to allow this step.

The ability to safety commission the drive after the main commissioning has been completed.

Another step that traditionally requires human interaction is the safety commissioning. This must be done online in TIA Portal using a separate, hard to-find tool. We have also automated this process. The user simply inputs four options into the block when adding it to the program and the rest is automatic.

• Do you want Safety Commissioning?

• Do you want control using Profisafe?

• Do you want control using the onboard terminals?

• What is the safety password?

The ability to save the drive parameters and hardware reset the drive programmatically.

When the tool has completed both the main commissioning and the safety commissioning it will automatically save the parameters in RAM to ROM. In the case safety commissioning, it also automatically triggers a hard reset of the drive after the RAM to ROM save. No need to go to the drive and cut power.

Time savings and flexibility

Using the Autonetics Drive Commissioning Tool the average runtime for both main and safety commissioning in less than a minute with zero effort or need for user interaction.

Compare this with a minimum five minutes for an advanced user to actively commission a drive. Now imagine needing to commission ten drives. The traditional route would require approximately an hour of active work by an advanced user to complete the task. The Autonetics Automatic Commissioning Tool would allow a user with minimal knowledge to complete the task in less than nine minutes.

It is this commitment to efficiency and understanding of the tools we use that sets Autonetics apart. This not only provides value to our customers in the form of cost and time savings, it also ensures the highest possible quality of work.

Contact Autonetics Today to discuss your custom automation needs.