At Autonetics we bring together the right teams of engineers and technical experts under one roof to deliver complete automated metrology applications. Our goal is to provide targeted solutions to precisely meet our clients’ expectations. This involves a close-knit program of design, testing and manufacturing capabilities.

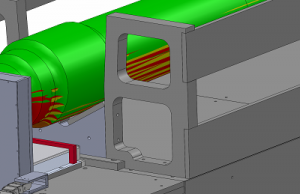

Mechanical and Electrical Design

By employing our own mechanical and electrical design engineers, our teams are able to work in a closed-loop environment. Each member of a project team is knowledgeable of all aspects of the project. Our design engineers work directly with the customer, visiting the production facility and working with their engineers and operators on the factory floor. The in-house designer knows well the company’s product and how to incorporate lessons learned in past projects while also adhering to Autonetics vision for exceptional, made-to-order products.

Software Design and Development

The level of customization is perhaps the biggest benefit of Autonetics software. While a commercial package, if available, may fit some application needs it is doubtful that it will have the same efficiency as tailored software. By meeting each client’s exact specifications Autonetics can cover every aspect of the application without unnecessary extras. It gives greater control in targeting the end user and the software makes the interface more familiar and instinctive.

By designing and programming the software in-house, Autonetics is positioned to provide immediate and intelligent support. Rather than dealing with technicians who may not understand the situation, support is provided from the individuals who have developed the software firsthand. They will understand any subtle nuances and minimize downtime from technical errors or mix-ups.

Component Manufacture

The foremost advantage for manufacturing in-house is the flexibility to change designs on the fly and quickly add features on request. This manner of manufacture allows Autonetics to move through the design, engineering, product development, and production phases quickly and easily.

With in-house manufacturing Autonetics can test trial components, discuss issues with our engineering and design departments, and then change what needs to be changed instead of waiting on third party lead times and shipping schedules. This radically speeds up development and cuts out what can often be weeks between design change and testing.

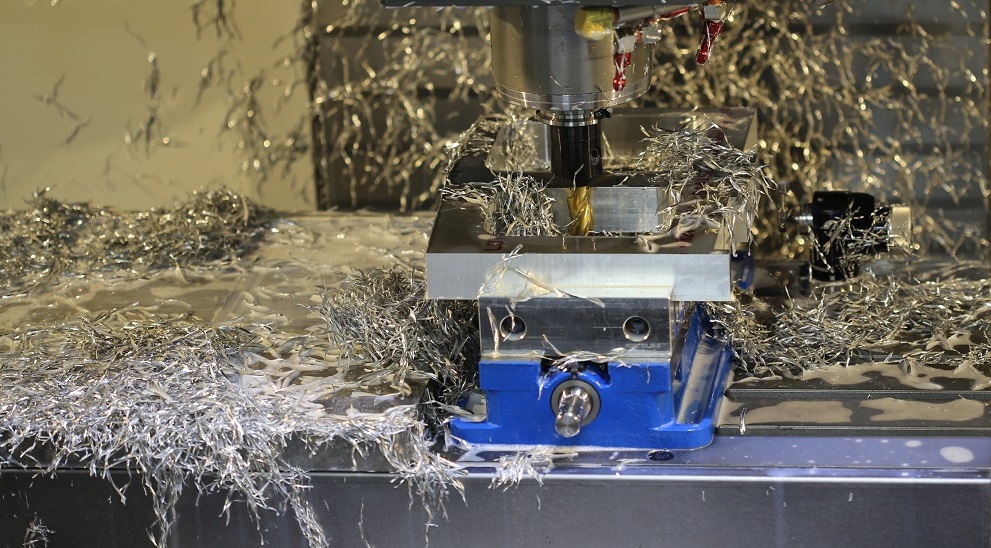

New Machining Capabilities

Continually expanding our machining capabilities, the Cary, NC facility now hosts a new CNC vertical machining center for the intricate and small features of modern tooling, this machine is suited to the wide variety of work pieces required at Autonetics for our precision metrology systems. Coupled with CAD / CAM software this gives us the capability to mill parts with close tolerances and complex shapes in quantities of one or one thousand.