Improving Quality and Reducing Costs

Automated Inspection & Gaging Systems can help companies to improve overall product quality and grow their business while reducing manufacturing costs, helping them to become more competitive in this difficult business climate.

Whether they are producing automotive, medical, consumer or virtually any other product, all companies have some type of quality inspection or gaging as part of their production process. Some companies specify that their production line operators are responsible for verifying product quality. Other companies utilize quality technicians offline to manually gage or visually check smaller audit groups of products to verify critical dimensions, the presence of features or look for defects. As machine vision inspection cameras and laser gaging sensors have become more cost effective, many companies are implementing automated inspection & gaging systems in their facilities. These systems can be as simple as standalone cameras or sensors integrated into existing machinery or as specialized as custom designed and built turnkey automated inspection machines. No matter what type of system is ultimately selected, automated inspection & gaging offers companies many benefits over the older manual processes and they can help companies to compete more effectively for new business.

Improve Product Quality

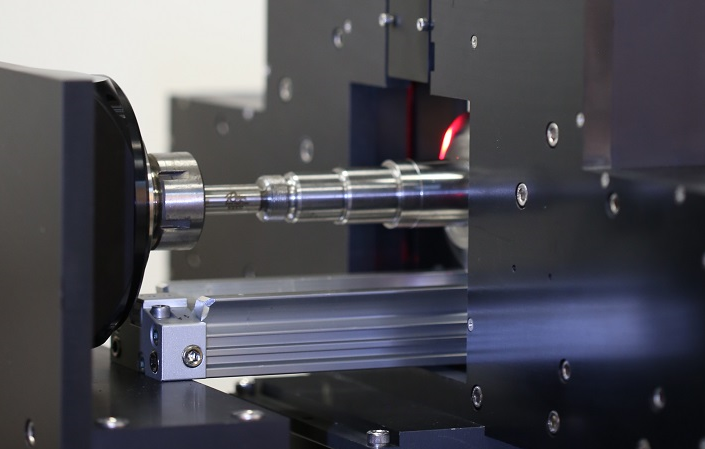

Properly designed and programmed automated inspection & gaging systems are very fast, accurate and repeatable. They virtually eliminate the human error content of most Gage R&R studies of manual inspection & gaging processes. Machine vision cameras can be programmed to automatically verify dozens of features on 100% of the products or assemblies produced in as little as a second. Precision laser sensors provide micron level measurement accuracy without even contacting the part. Manual inspection, on the other hand, is highly labor intensive and error prone. Operators must rely on detailed work instructions, hand held measurement devices, and they can be easily distracted while in the middle of checking the product.

Grow their Business

Customers demand continuous improvements from their suppliers which includes better product quality backed by statistical data. Automated inspection & gaging systems can be programmed to collect pass/fail results data for every feature checked on 100% of the products and then automatically record that data to several file types. Manual inspectors could collect and then enter the same type of data, but it may prove to be inefficient and potentially laced with errors. Companies that implement automated inspection generally highlight those systems during their customers’ visits to demonstrate that they are proactive with new technologies and the best choice to support their new business.

Reduced Manufacturing Costs

Labor tends to be one of the highest costs for manufacturers. As the training level moves up from line operator to quality technician, labor costs grow even higher. Moreover, complex products can take longer to inspect, so additional operators may be required to keep up with the desired production rate. Finally, an operator must actually be present to inspect the product, so if a company has multiple shifts these costs can be 2-3X the primary shift cost. On the other hand, automated inspection & gaging systems are very fast onetime investments that can be utilized 24/7 with little to no additional costs. Companies can monitor the inspection results data and then immediately correct process problems that cause rejects; therefore reducing scrap and improving line efficiency. One hundred percent inspection should also help companies to avoid the cost of containment and re-inspection that typically is the result of audit only inspections, machine or operator errors.

Types of Automated Inspection & Gaging Systems

There are 4 principle types of automated inspection & gaging systems. First, machine vision cameras and/or precision laser measurement sensors can be integrated into a company’s existing machinery or process. This is the most basic and the lowest cost way to get started. Technology Distributors are available to assist companies that have very simple inspection requirements. Systems Integrators are normally called in if the application requires more complex programming and support. Next, these same vision cameras and/or laser sensors could be installed inside of enclosures with light guarding, a pass through conveyor, a reject device and controls to separate good products from bad products. These entry level automated inspection & gaging systems are available from qualified integrators and suppliers that have programming, design and build experience. These suppliers routinely work with companies to help them specify systems based upon the product to be checked. Third, Turnkey Automated Inspection & Gaging Systems are highly customized machines with multiple cameras or lasers and are designed specifically for a single part or a closely related family of parts. These machines are sometimes referred to as sorting machines because some of them can run 24/7 lights out. They usually include automatic feeder bowls, material handling, reject containment, good box full counters, packing and labeling options. Finally, the most flexible type of automated inspection & gaging systems utilize robots to move either the part or the camera/laser around for multiple inspections on more complex parts. These systems can be designed to process the widest variety of parts since the robots are programmed to accurately move to a large number of positions. Additionally, the robots can be equipped with end of arm grippers for double duty as the systems’ load/unload pick and place device for even more flexibility. Robotic and Turnkey Automated (Sorting) Inspection & Gaging Systems are available from specialty machine manufactures and the most experienced integrators.

How to select an Automated Inspection & Gaging System and Supplier

Companies should consider several factors when choosing the best automated inspection & gaging systems for their facility. These should include: initial system cost, current (and future) production rate, production flow, single part or family of parts to be checked, and what other value added or labor saving features could be implemented at the same time as the automated inspection & gaging system. In the end, the most important factor is usually return on investment, but surprising to many companies, automated inspection & gaging systems can have a payback of less than 12 months. To be fair and even more appealing the ROI calculation should include some form of good will and expected new business that may be indirectly related to the new automation. When selecting possible suppliers companies should review the automated inspection & gaging systems suppliers’ websites for their standard inspection products and their years of proven machine vision and laser integration experiences with the same or very similar products. Some engineering firms and custom machine builders may mention automated inspection in addition to other services that they provide, but since this technology is changing rapidly it is best for companies to select experienced suppliers that specialize in machine vision and laser gaging systems. Some of them even offer free inspection and gaging project evaluations which is another good place to start. Finally, during the initial call or meeting with a new automation system supplier, companies should provide as many details about the product and process as possible. Experienced suppliers should demonstrate to the company a solid understanding of the requirements, the inspection & gaging technology to be integrated, and offer creative and cost effective solutions that benefit the company over the length of the product life.

By: Phillip Smith