Manufacturing within the United States is in the process of revitalization. Companies across the country are moving to close the gap spatially and temporally between manufacture and metrology. This effort to improve efficiency and lower cost will require tighter integration of gauging sensors and real-time error correction of machine tools.

Consequently, new measurement solutions for a growing number of parts produced in lights-out operations are in demand.

Although off the shelf products are available, shorter cycle times and elevated tolerances have begun to approach the envelope of existing technology in OD measurement devices. Couple this fact with ever-increasing part tolerance requirements and you’ll soon hit a wall in current generation data collection technology.

“Man is a tool-making animal.” — Benjamin Franklin

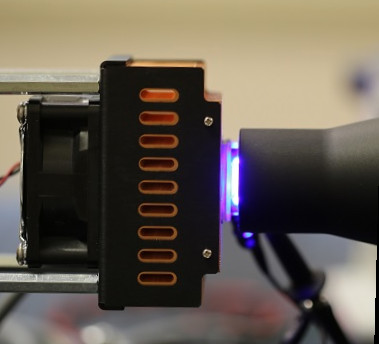

From its inception Autonetics has been dedicated to bringing all aspects of turn-key gauge manufacture in-house. By gaining direct control of the development of hardware and software, Autonetics has set itself apart from other metrology companies. To that end and along with our on-going software development efforts, Autonetics is yet again raising the bar by investing in research, development and testing of high-speed gauging sensors. This new endeavor will bring optical design, multi-layered board blueprinting and fabrication, illumination design and mechanical packaging all under one roof.

This new technology will allow Autonetics to stay at the cutting edge of high speed, non-contact metrology. Autonetics goal is to build systems that are freely adaptable and scalable with regard to future automation levels, software interfaces and tight integration with CNC’s working in the harshest environments.

Look for trial results in March, 2014.