High Tech Inspection, Small Footprint

Autonetics-designed inspection systems are fast, accurate, and repeatable. They eliminate the human error affecting reliability and repeatability. Manual inspection is labor intensive and error prone. Operators must rely on detailed work instructions, hand-held measurement devices, all the while avoiding distractions and fatigue. Autonetics SGU line of automated part gauges are designed and programmed to measure any number of features on 100 percent of the products or assemblies produced. Precision state of the art sensors provide micron-level measurement accuracy without contacting the part.

Modern manufacturing processes must successfully support a multitude of options. High model mixes, complex product combinations, and unique short-run parts push traditional metrology systems to their limits.

SGU gauges provide an expansive measurement system to accommodate today’s demanding manufacturing requirements. By incorporating the Autonetics metrology suite 4.1, the SGU line has been proven to successfully support high part family mixes, with new parts capable of being added on the fly.

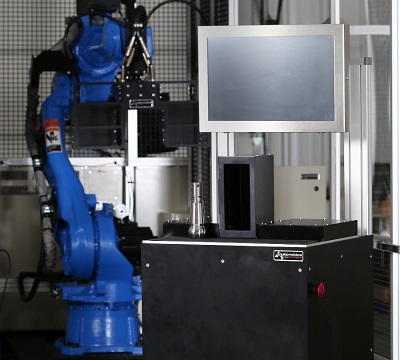

Fixed Position Gauges

Utilizing part positioning fixtures to support larger work pieces these gauges are used to capture dimensional data on parts with dimensions (up to 14 inches in diameter) and heavy components (up to 550 lbs).

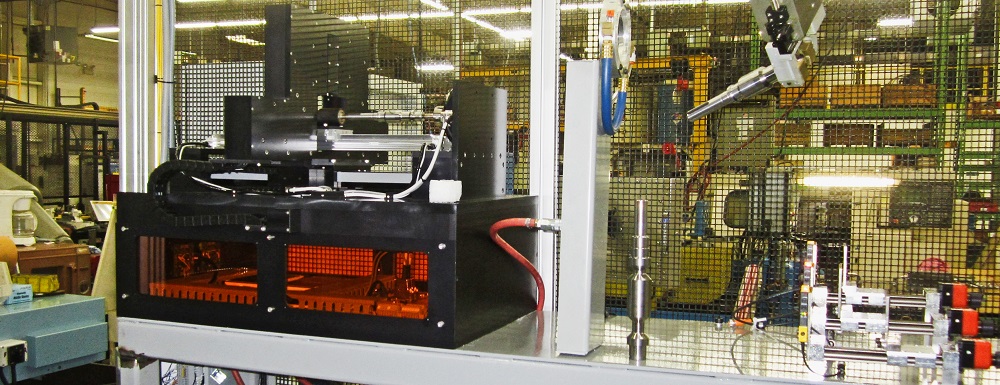

Mobile Gauges

A product inspection application that can be shared with any number of CNCs that verifies part conformance in relation to each individual machine, design specifications and confirm whether critical tolerances and quality standards are being met.

Hardware

- Hardened and sealed machine tool recirculating ball bearings

- Precision ball-screw drive system

- Portable stand with locking casters

- Hardened steel linear guides enhance precision, reliability and durability

- Bellow covers protect critical components from shop floor contaminants

- Advanced Geometric Thermal Compensation

- Modern, high-tech materials minimize environmental effects on measurement

Customers demand better product quality backed by hard data. Autonetics SGU gauging systems are programmed to archive results for every callout on every part and export that data to your quality control system for complete traceability. With auto-compensation software the same data can be sent to the CNC for automated tooling offsets to immediately correct process problems that cause rejects, in so doing, reducing scrap and improving line efficiency.