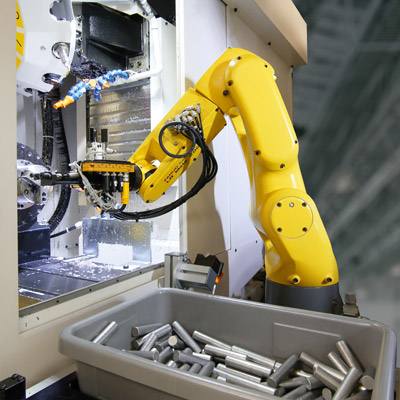

Autonetics is an experienced, full turn-key supplier for custom machine tending solutions. Whether the application is machining, grinding, heat treating, spinning, molding, or tending another process machines, Autonetics has the capability to design build and integrate our solution to your specific needs. In addition to the machine tending process, Autonetics has experience in inspection, handling and other value added operations.

For personnel, machine tending can be dull and dangerous work that requires consistency and unwavering attention to the production process. Robots are ideally suited for this type of work, performing repetitive or dangerous tasks hour after hour, flawlessly without supervision. They tend all manner of apparatus from CNC and fabrication centers to hot casting and forging.Benefits of automated tending:

Repeatability:

- Robotic machine tending is more accurate – minimizing problems that can occur when parts are placed in machines incorrectly.

- Productivity: Throughput increases with automation as the machines can run more rapidly and more frequently.

- Savings: Labor costs decrease as fewer human resources are necessary. Production benefits increase with a quick return on your investment.

- Support: Remote control of the application allows immediate access for trouble shooting and reprogramming, saving time and expense.

- Safety: Robots provide greater safety. Workers are spared from interfacing constantly with potentially dangerous situations, and exposure to potential injury.

Standing behind our product is of primary importance to Autonetics business principals. We are dedicated to providing our customers with superior warranties and support in order to ensure that your experience with Autonetics service is consistently dependable and effective.