SGU-H3At Autonetics we manufacture rugged gauges designed for years of service on the factory floor. Autonetics H series gauges provide short and long term advantages that help you consistently produce better parts. Reducing manufacturing defects goes directly to your bottom line and makes for a rapid return on investment. Autonetics offers fully automated options designed for precision measurements. Our rugged gauging unit makes inspection and off-setting multiple CNC machines a “hands free” procedure. Utilizing advances in sensor technology we have brought significant improvements to in-process OD and ID gauging.

Providing turn-key, lights out applications for our customers assures that the accuracy and repeatability of measurements doesn’t depend on the skill of the operator. Autonetics guarantees that every measurement taken with our Horizontal series SGU is verifiable, repeatable and accurate.

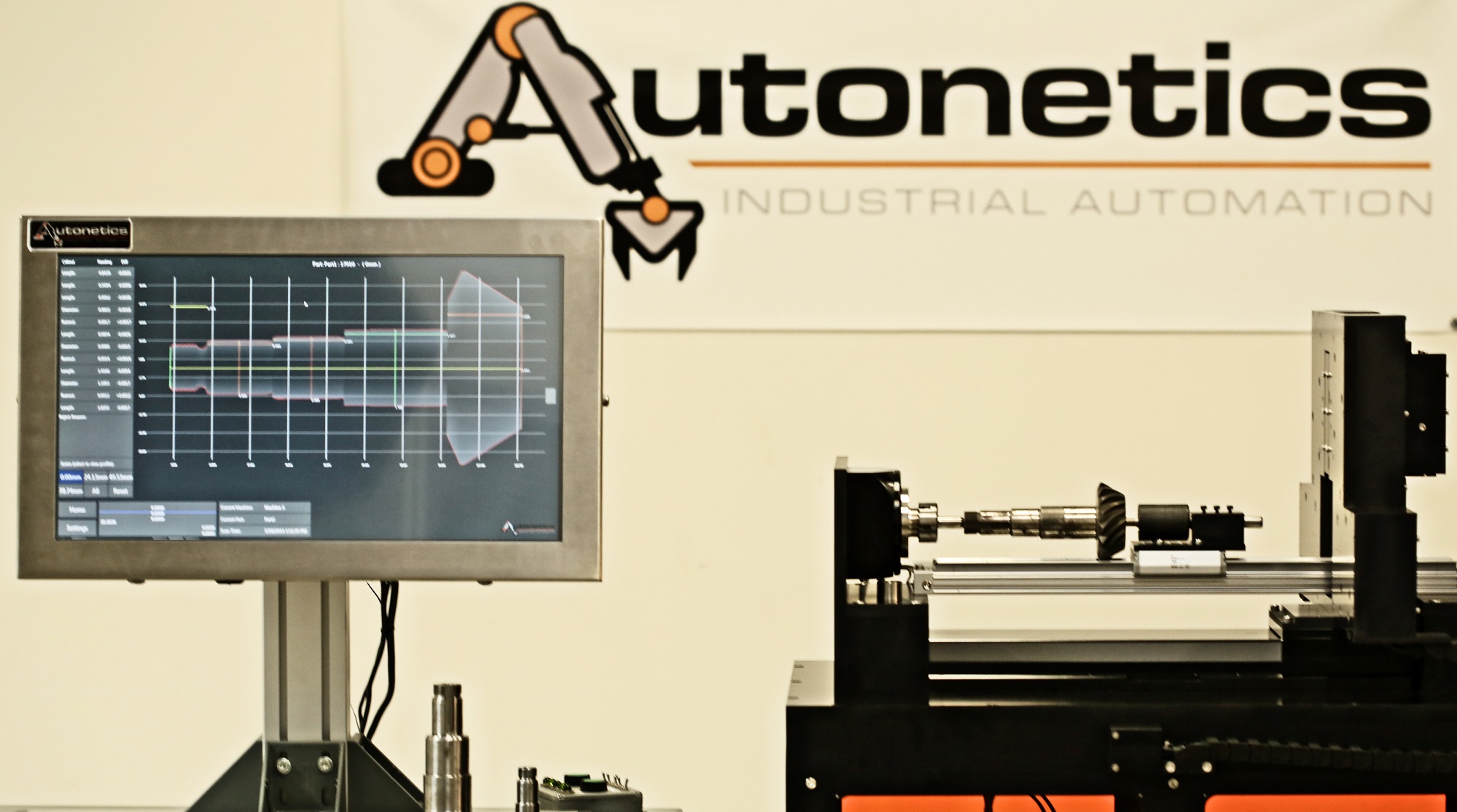

The SGU-H Series includes meticulously ground telecentric optics for precise focus with long-life LED light sources and high resolution imaging. Autonetics powerful metrology suite software is developed and supported in house here in the US of A. It includes an industrial, 23 inch, wash down rated touch screen display, running Autonetics AMS software, showing the desired selection of part profiles, measurements, gauging graphics and results.

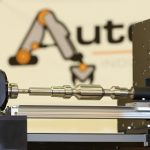

Our SGU- H Series includes the complete inspection station, including actuators and fixtures for the gauging platform. Placement and removal of the product cam be performed by a human or robot. Most systems are designed for free-standing or cell mount versions however custom mounts are available.

The H series is ideally suited to inspect a huge selection of turned parts to include; short and long shafts of large and small diameters, pins, axles, pinions, motor shafts, PCP rotors, threaded pipe fittings, valve components, cams, spindles and many more work pieces.

Autonetics graphic user interface is easy to navigate and simple to use. The powerful and friendly software engine allows our customers to take total ownership, including the ability to quickly and economically make changes as new products and missions are introduced over the years.

- Automatically identifies and loads callouts for any number of individual parts

- Measures all outside diameters

- Measures distances between snap ring grooves, shoulders, journals

- Identifies and measures Keyway depths, widths and true position

- Scans for runout at each journal / TIR of all journals

- Gauge services multiple CNC’s offsetting all machines

- Fully automated load/unload (lights out)

- Data export to CAD.

You might think that precision non-contact metrology and a shop-floor environment would not mix, but that’s exactly what many of our customers are doing. Autonetics SGU-H family of instruments offers solutions that provide a cost-effective path to success.