Gaging solutions for large and small diameter shafts, cams, spindles or axles.

Autonetics patented process of non-contact robotic gauging addresses a lapse in quality control concerning the turning, shaping and fabrication of items. Our product specifically addresses measurement of item dimensions while still in the process of construction. Additionally the laser micrometer measures these dimensions without the need to be in contact with the item. To date, gauging has required the item to be measured be removed from the means of manufacture or that the process of manufacture be suspended. Our unique gauge allows manufacture to continue, with increased quality control by allowing up to one hundred percent of production to be tested without overly slowing manufacture.

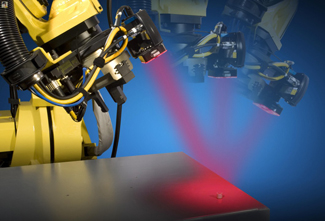

Additionally, it allows real-time adaptive tuning of the machining process by interfacing with the CNC control. In process non-contact gauging utilizes machine mounted articulated robotic arms to position a laser micrometer or laser profile sensor in close proximity to a part or item during the process of manufacture. The laser micrometer then measures the required area with accuracy down to 1micron / 0.00004 inch with certain applications. The micrometer sends a signal to a computer where, through our software, the measurements are integrated with a computer numerical control machine tool (CNC). If at this point the measurements do not meet specifications for the item, a proprietary software program directs the CNC machine to adjust tool compensation and tool wear offset. The software program allows the operator to interface with the gauging system to view results and customize gauging parameters.