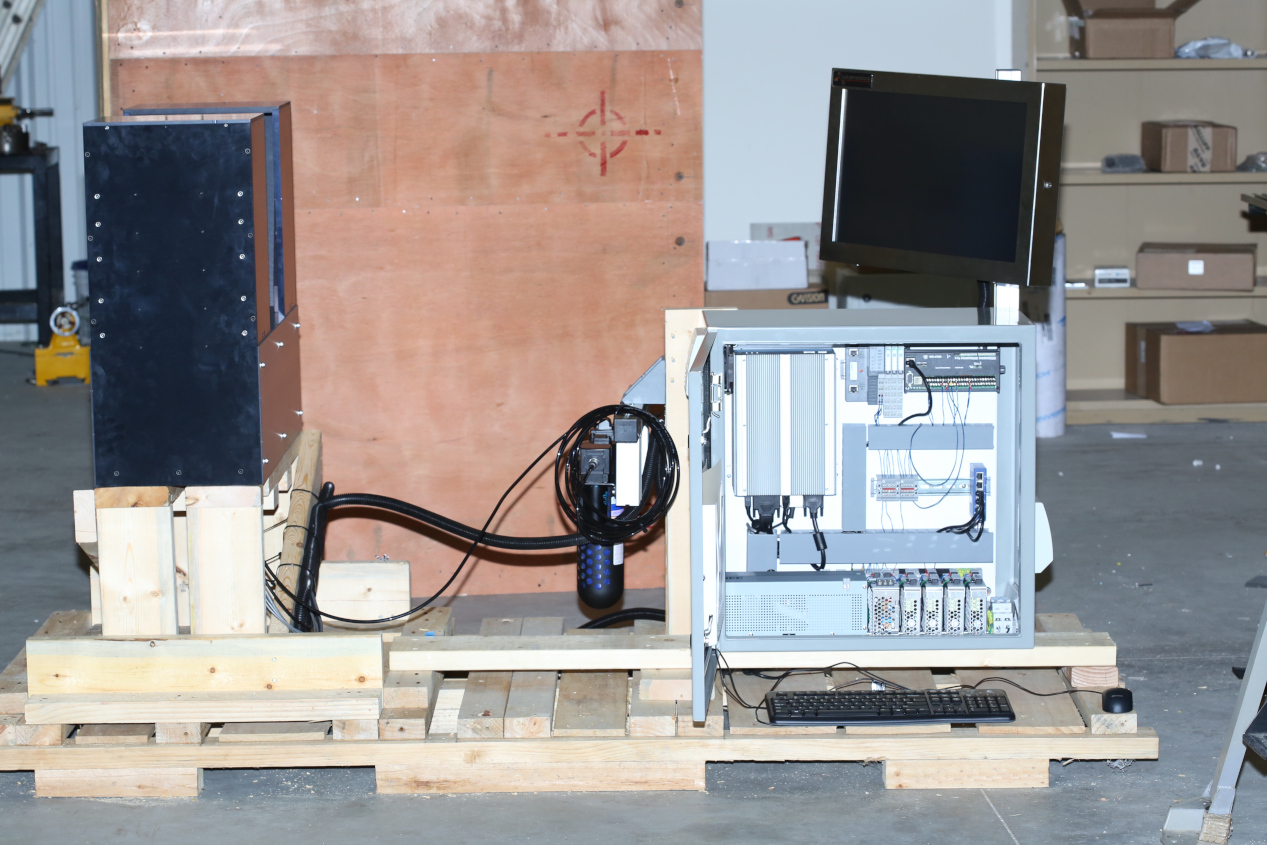

Every inspection system built by Autonetics is hand crafted by industry veterans with a passion for quality. We focus on the details that matter most: durability, reliability, and accurate results. Our dedication to our craft means you can spend your time doing what you do best while knowing the quality control is under control.

+1 919-542-4417

-

Category

Inspection Purpose

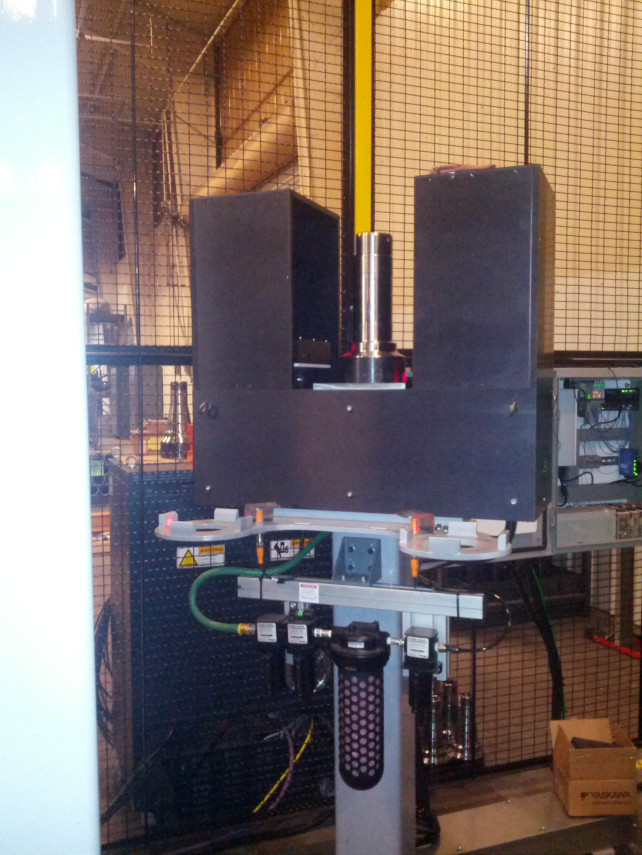

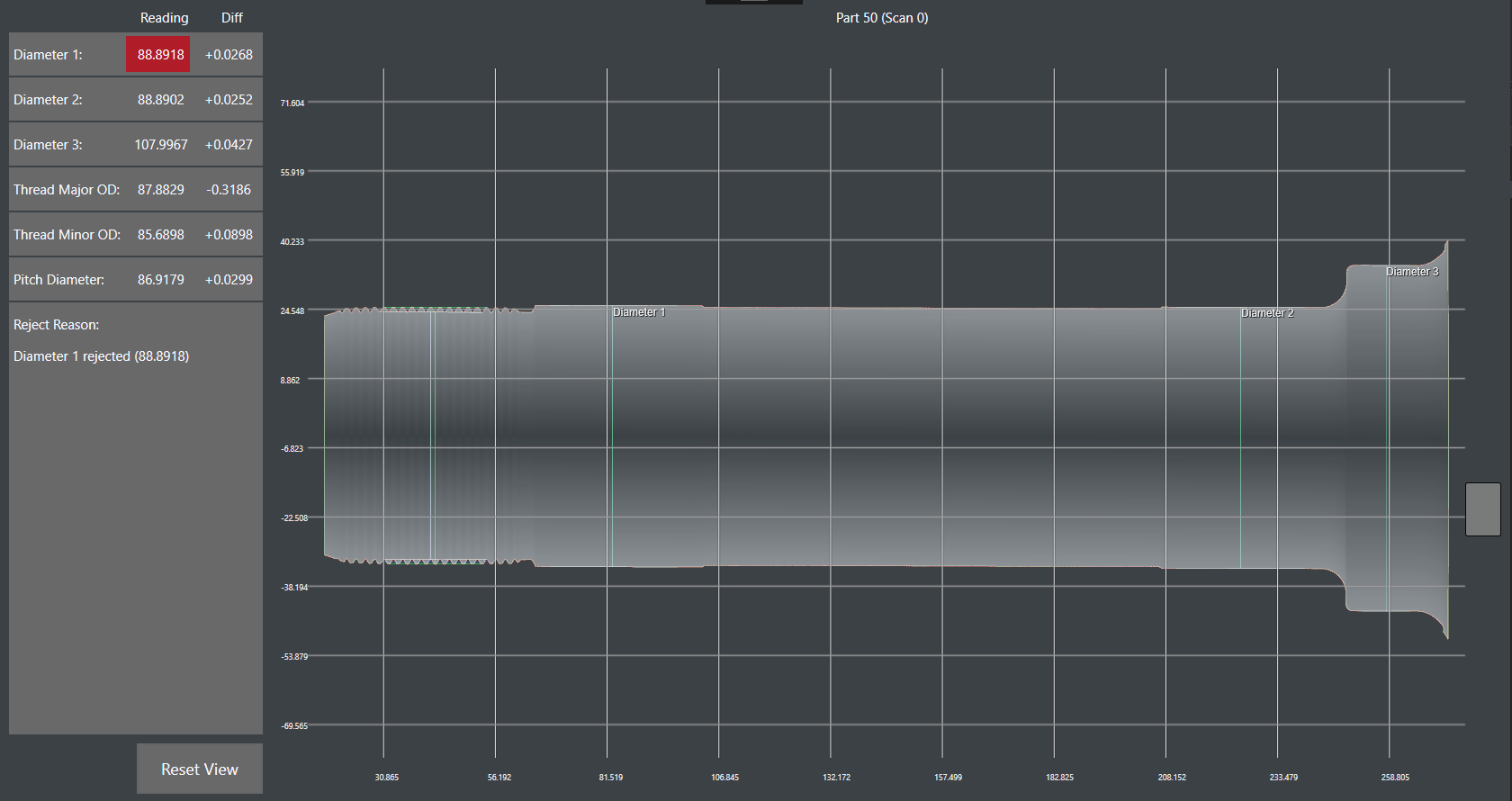

Truck Axle InspectionClient

SAF HollandIndustry

AutomotiveLocation

Warrenton, MOGauge R&R

< 10%Cycle Time

20 sec