Why does a coupling need to be deburred?

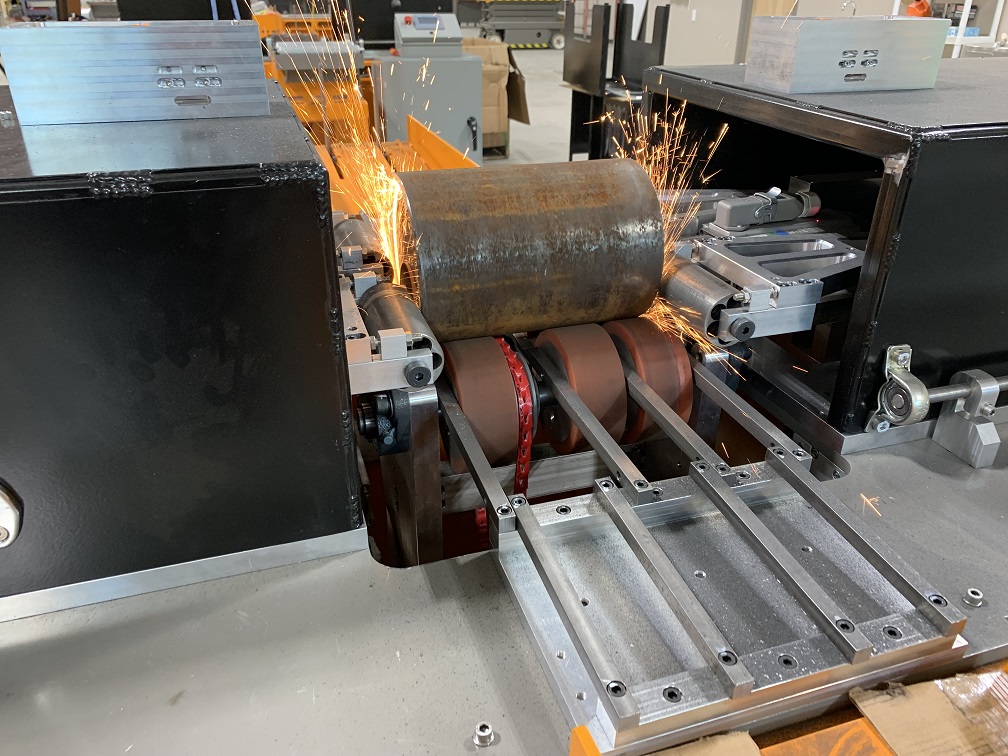

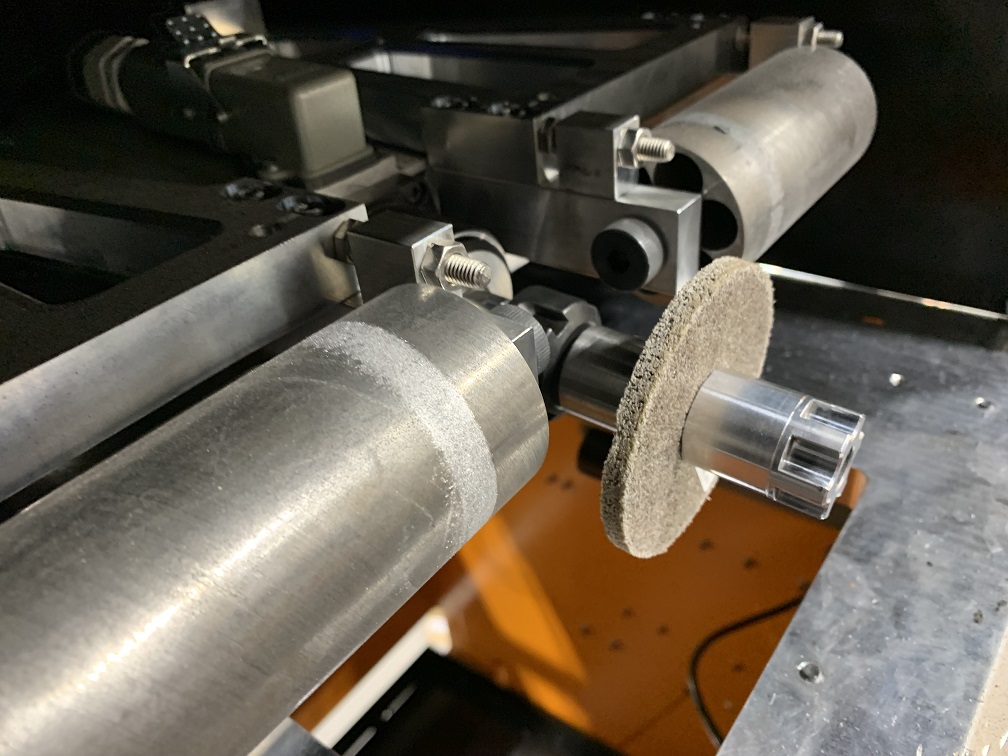

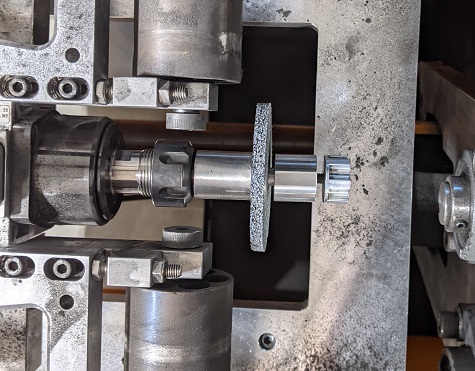

In high-speed coupling manufacturing facilities, PMC threaders are typically employed for machining of threaded couplings. While these types of threaders can quickly and accurately cut a thread, an artifact of the process is a sharp burr on the first thread on both sides of the coupling.

If not removed, this thread can lead to galling when a pipe is threaded into the coupling. This galling can result in negative performance characteristics of the coupling-pipe connection.