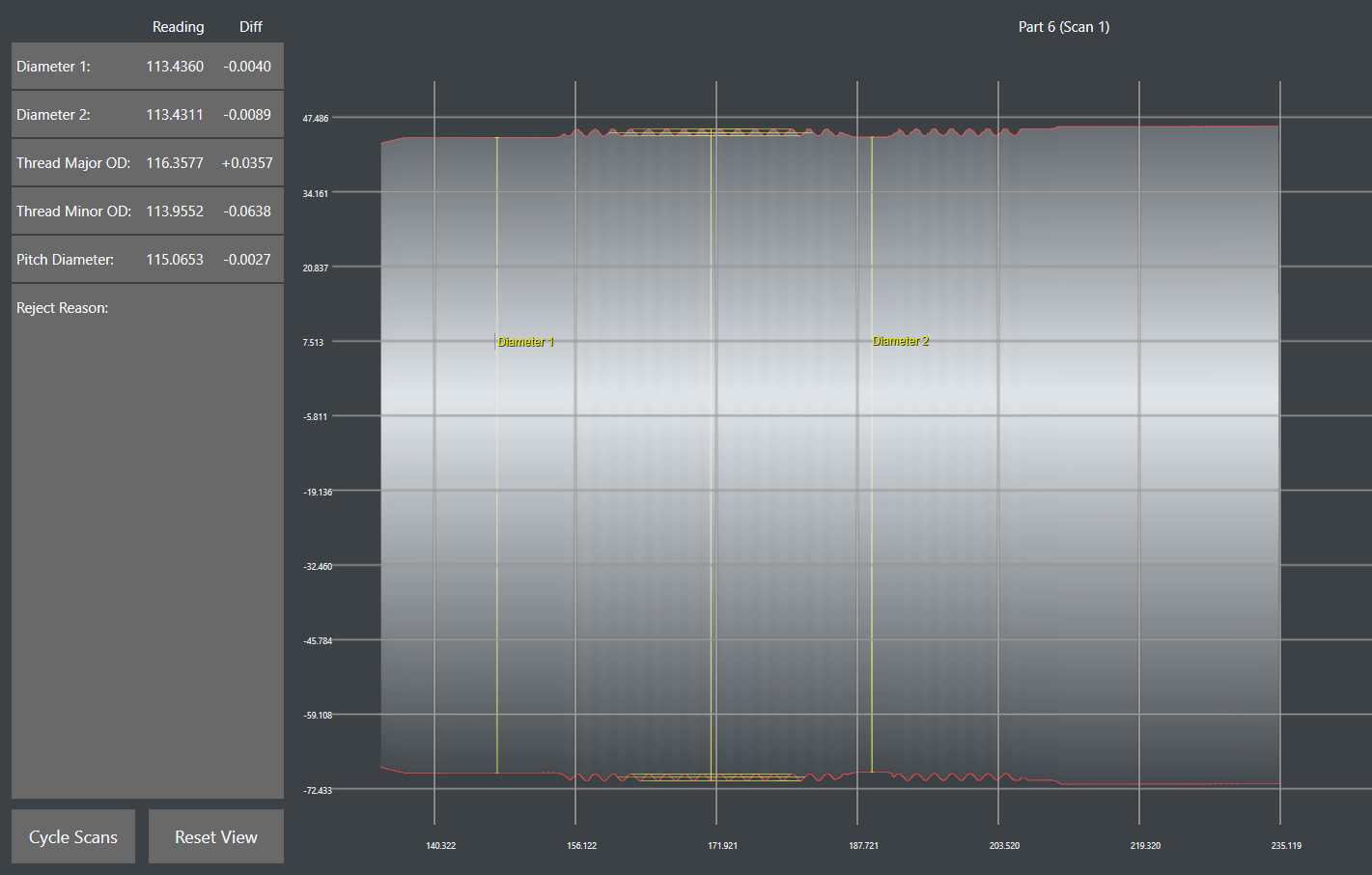

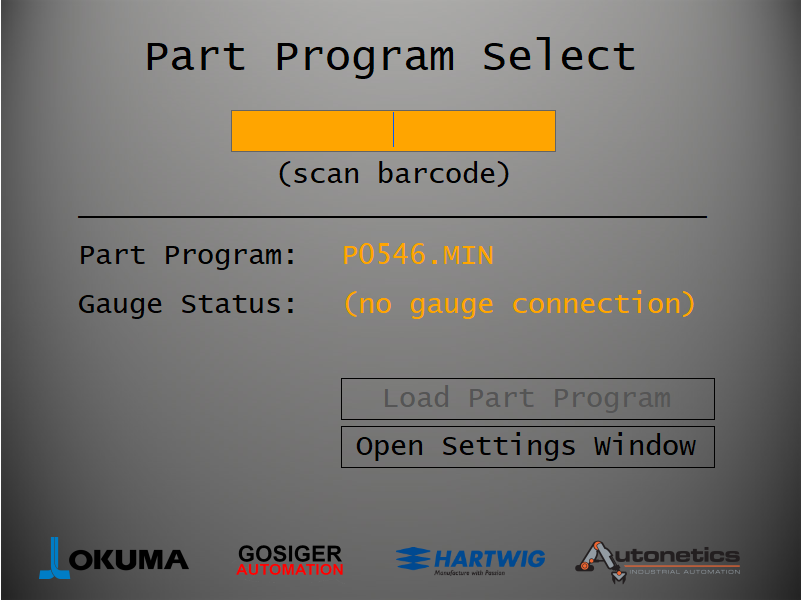

In addition to providing the inspection system, Autonetics developed a software application that runs on the Okuma Control. This software allows the operator to scan a bar code which contains details about the part. This information is automatically sent to the gauge allowing for the correct work holding to move into place and also tells the system which tolerances to use for subsequent part scans.

+1 919-542-4417

-

Category

Inspection Purpose

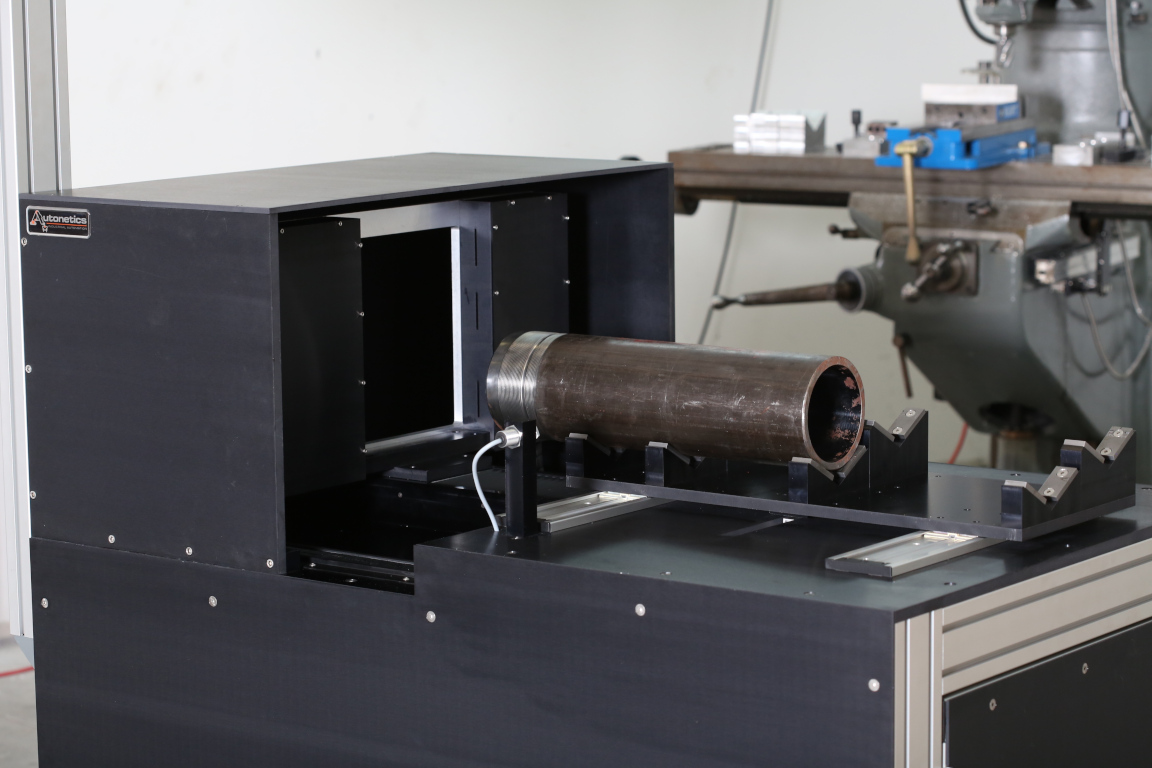

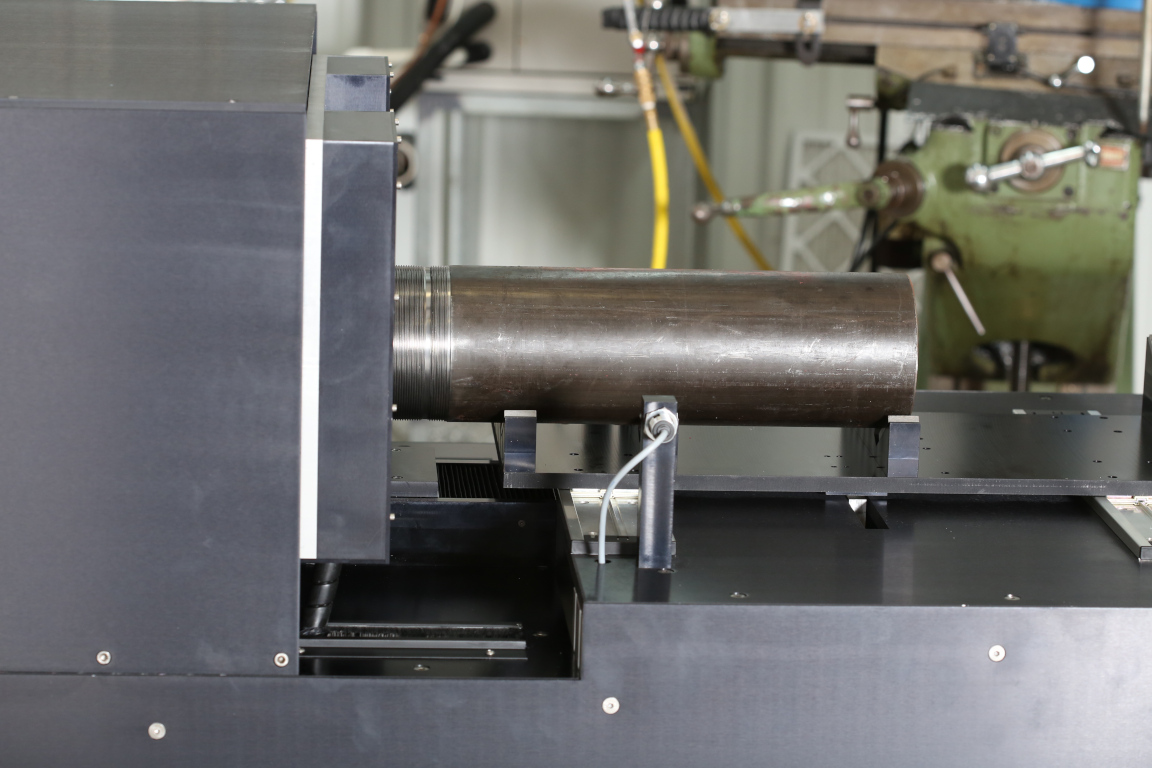

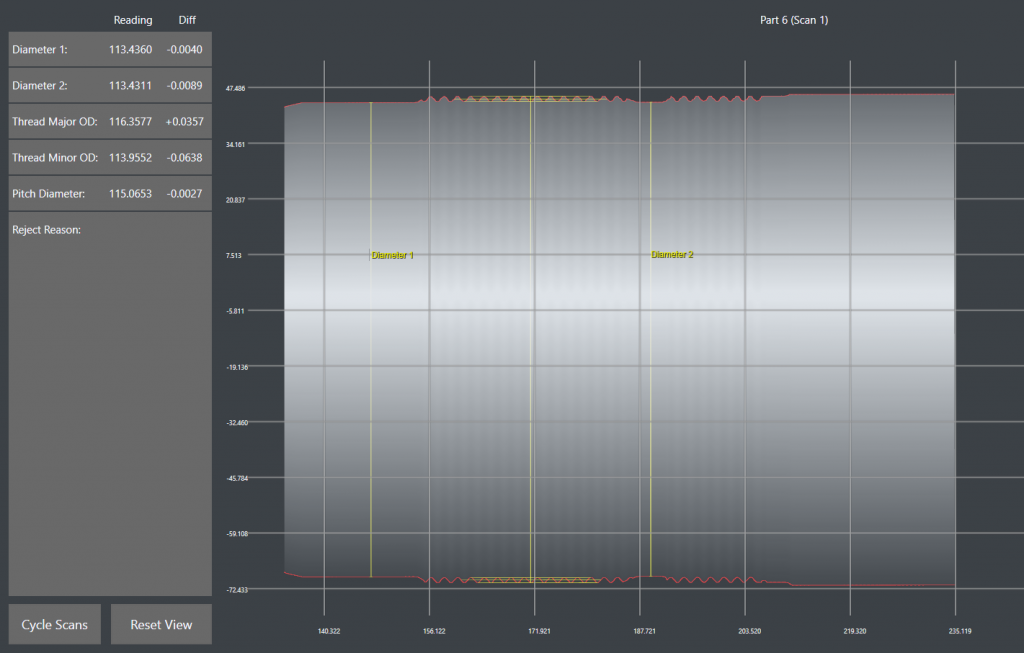

Cylinder OD and Thread InspectionClient

John DeereIndustry

IndustrialLocation

Moline, ILGauge R&R

< 10%Cycle Time

40 sec